pendulum impact test procedure|hit pendulum impact testers : exporting The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum . Resultado da Photopea: advanced image editor. Free online editor supporting PSD, XCF, Sketch, XD and CDR formats. ( Adobe Photoshop, GIMP, Sketch App, .

{plog:ftitle_list}

Resultado da 640K followers • 27 following. Posts. About. Photos. Videos. More. Posts. About. Photos. Videos. Intro. Página Oficial da apresentadora Catia .

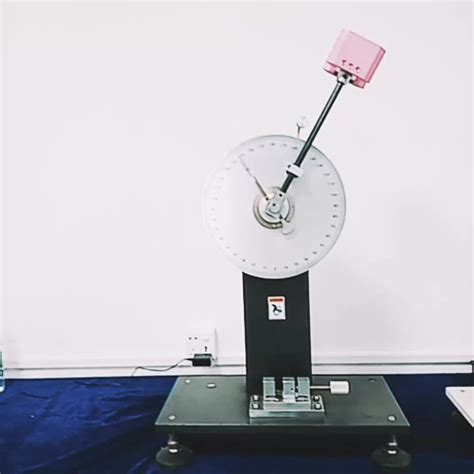

Pendulum impact testing machines are critical to validating the performance of polymer, composite, and light alloy materials when subjected to an impact. Selecting the right pendulum for the application is key to maximizing throughput, repeatability, and operator safety. This guide .The most common configuration for pendulum impact test are Izod and .

Selecting the correct device is key to ensuring repeatable pendulum hammer . Pendulum Charpy/Izod Impact Testing is a high strain-rate test to determine the amount of energy absorbed by a material during fracture.The Impact tester involves a pendulum of known mass and length which is .The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum .

An impact test works by striking a properly prepared and fixtures test specimen with a weight, either from the side or from above. For Charpy and IZOD impact tests, a pendulum with a weighted hammer is released from a . The Izod impact test fixes one end of a notched specimen in a cantilever position by means of a vice. A striker on the arm of a pendulum or similar energy carrier then strikes .

Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180. The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. This singular point test offers a .

Notched Izod Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and .• Impact Test Procedures. • Fracture Toughness Assessment from Impact Test Data. STP 1380 marks the 100 year anniversary of the invention of the pendulum impact test by S. Bent . Selecting the correct device is key to ensuring repeatable pendulum hammer impact test results. Here are some key considerations and features to look out for to maximize efficiency, safety and accuracy.

Pendulum impact testing machines are critical to validating the performance of polymer, composite, and light alloy materials under real-life conditions. Selecting the correct pendulum .

In addition to the high energy impact models, Tinius Olsen manufactures a range of low energy pendulum impact testers that can also be easily changed from a Charpy to an Izod configuration. These testers come in a couple of .The process involves using a specialized machine with a swinging hammer, known as a pendulum, which strikes a small piece of the material being tested. This material contains a small notch to facilitate the breaking upon impact. .establishing global standardized testing procedures. The multi-language interface and compliance with ISO and ASTM standards make it a good choice for global institutions and corporations. . Charpy pendulum impact test EN 10045-1 Charpy impct test on metallic materials GOST 9454-78 Metals impact test at low, room and high temperature Pendulum . Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. . Figure: Test setup for Charpy impact test. A deflected pendulum hammer is then released from a certain height. At the lowest .

Place pendulum in release position and rotate the drag pointer counter-clockwise until it comes to rest against adjustment screw on pendulum arm. 8. Procedure 8.1 Apply sufficient water to cover the test area thoroughly. Execute one swing, but do not record reading. NOTE 2—Always catch the pendulum during the early portion of its return swing.

1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact . Chip impact test procedures. The chip impact test was originally developed in order to measuring the effect of surface microcracking caused by the weathering. The toughness of the material is measured in this . Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180 The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. This singular point test offers a straightforward quality control measure to determine a material's specified impact chara Abstract Pendulum impact testing is widely known to have a history that extends back to the turn of the last century. To many researchers today, instrumentation of the impact test to acquire a load-time history, and thereby provide important data in addition to absorbed energy, is usually considered to be a relatively recent development.

Abstract This publication consists primarily of the papers presented at the Second Symposium on Pendulum Impact Machines: Procedures and Specimens, sponsored by ASTM Committee E28 on Mechanical Testing and its Subcommittee E28.07 on Impact Testing.

Abstract: Pendulum impact testing is widely known to have a history that extends back to the turn of the last century. To many researchers today, instrumentation of the impact . Korber et. al.7 used a procedure similar to that of Honiger to achieve measurement of the . Testing”, , , T. A. Siewert . . . . . . .

• Impact Test Procedures • Fracture Toughness Assessment from Impact Test Data. STP 1380 marks the 100 year anniversary of the invention of the pendulum impact test by S. Bent Russell, and the research and standardization efforts of G. Charpy during the early part of the 20th century. As an added bonus, reprints of two landmark papers . The pendulum will hit right above this to break the material. You’ll want to have a vertex that sits at the midpoint of the length of the test material. Then, add the test material to the pendulum testing apparatus, at the bottom where the pendulum will swing and make contact. Secure it with the vise. Abstract. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests. Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity. The status of related test .

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .PENDULUM IMPACT AND TOUGHNESS TEST METHODS1 By JOHN T. DROW,2 Engineer, L. J. MARKWARDT,3 Assistant Director, and W. G. YOUNGQUIST, Engineer . In the interest of unifying test procedures, the same size specimen used for the pendulum impact (2 centimeters square in cross section) was adopted for the toughness test method. An exten- Pendulum impact tester (WP400) Figure 1 — Pendulum impact tester (WP400) 1 — Anvil, 2 — Hammer, 3 — Scale; . Charpy Impact Test — Procedure & Importance ! — [Civil Planets]. [online .

The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of ISO documents should be noted. . Pendulum Impact Testing: A Century of Progress . Instron is always available to provide further guidance and help you identify the correct test method for a specific material. Step 2: Know your standards. Once you have identified the correct pendulum hammer impact test method, always refer to the relevant industry standard. ISO 179 and ASTM D6110 cover the Charpy pendulum impact test. The Charpy test is used to determine the resistance capacity of metal (steel) specimens against the sudden impact of a pendulum that swung from a certain height. The Charpy impact is also known as the Charpy V-notch test because the specimen used in this test is cut at a certain depth in a ‘V’ [.]

pendulum impact tester price

5.2 The pendulum impact test indicates the energy to break standard test specimens of specified size under stipulated parameters of specimen mounting, notching, and pendulum velocity-at-impact. . By invoking this procedure, ASTM does not waive any of its rights to enforce this Agreement or to protect its intellectual property by any other .

Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated .This procedure for evaluation of machines had the distinct advantage of requiring only measurements of quantities that could be traced to national standards. . et al. European certification of Charpy specimens: reasoning and observations. In: Pendulum Impact testing: A Century of Progress, (Siewert T.A., Manahan M.P., eds.). ASTM . A procedure for the calibration of the strain gauges located on the pendulum blade and calibration of the recording system and amplifier blockt for three different signal levels is described. . E.A., Zhmaka, V.N. et al. Instrumentation of a Pendulum Impact Testing Machine for Impact Bending Tests. Strength Mater 54, 850–856 (2022). https .

3.2 The test surface is cleaned and thoroughly wetted prior to testing. 3.3 The pendulum slider is positioned to contact a specific length of the test surface prior to conducting the test. The pendulum is raised to a locked position, then released to propel the slider across the test surface. 3.4 A drag pointer indicates the British pendulum .

The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .applicable to machines with 2mm or 8mm strikers used for pendulum impact tests carried out, for instance, in accordance with ISO 148-1. It can be applied to pendulum impact testing machines of various capacities and of different design. Impact machines used for industrial, general or research laboratory testing of metallic materials inTo determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :

Fully Automatic Seal Tester vendor

Semi-Automatic Seal Tester vendor

webPoppy Playtime Official Store. Digital Gift Card Regular price $25.00 USD Regular price Sale price $25.00 USD Unit price / per . Sale Sold out Shipping calculated at checkout. Denominations $25.00 Variant sold out or unavailable $50.00 Variant sold out or unavailable $100.00 Variant sold out or unavailable .

pendulum impact test procedure|hit pendulum impact testers